Previous research focused on artefact-based analyses, which whilst of undoubted value, has created a disparity in the discussion of the technology of Beaker period and Bronze Age metalworking in Britain. A discussion of artefacts with a heavy emphasis on ore geologies has occurred, whilst the location and organisation of metalworking (other than mining) within society has been a speculative discussion based on little excavated evidence. The reasons for the under-representation of smelting and/or casting sites within the Beaker period and Bronze Age could be hypothesised to be the product of prehistoric societal factors. Perhaps, as indicated by ethnographical study (e.g. Eliade 1962; Budd and Taylor 1995), metalworking such as casting only occurred in specific places, governed by strict social roles, and these locations have yet to be identified successfully. An alternative explanation could be that archaeologists have investigated many sites where evidence of copper/bronze working was present, but it was not obvious or identifiable during excavation. It is possible that the evidence from metalworking is not necessarily visible at the macroscopic excavation level and requires analysis on the microscopic level to identify residues.

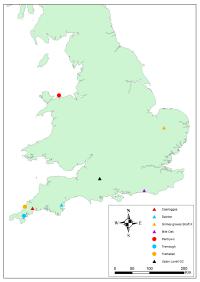

Five broad stages can be defined in the early metalworking process for copper and bronze (Table 2), with each stage having the potential to produce slightly different types of archaeological evidence. A small smelting furnace would not necessarily need to have a refractory lining and could easily occur within a feature such as a conventional hearth/fire pit with a directed air supply, with the ore smelted using crucibles, although there is scant evidence for any copper or tin smelting in Britain during this period (Roberts 2009, 468–70). Such smelting of copper and tin ores would render the process 'archaeologically almost undetectable' (Ottaway and Roberts 2009, 206), especially if little slag is produced or it is removed, potentially as part of the symbolism attached to the process. Likewise, melting/recasting could also have occurred in a small hearth using crucibles and a directed air supply (Figure 2). During archaeological excavation, whether such a feature would be recognisable as a metalworking hearth/furnace is doubtful, especially if there is no other circumstantial evidence, such as metalworking tools, crushed ore residue, slag, casting debris or furnace lining (Timberlake 2005, chapter 11). In such instances, if a feature is found containing evidence of heating and no other circumstantial evidence, is it not more reasonably interpreted as a hearth, which of course it could well be as well (see below, Tremough). Thus the identification of metalworking evidence in the Beaker period and Bronze Age is problematic, especially if features, such as pits with evidence of heating, are not associated directly with other artefacts used in the metalworking process. The current evidence for metalworking (excluding mining) within southern England (and Britain more generally) is slight, and can be broadly segregated into direct in situ excavated evidence and indirect evidence (Figure 3).

Direct evidence for excavated metalworking structures, in the form of slag, prills, furnace structures, furnace artefacts and metalworking hearths (Timberlake 2005, 198), is extremely scarce from the British Beaker period and Bronze Age, although as postulated, this is possibly due to the non-identification of evidence, as well as a scarce archaeological resource and limited survival. The most definitive evidence for early Beaker period smelting of copper comes from the settlement site at Ross Island, Ireland, which whilst outside the primary area being considered, is included for the evidence of its smelting structures alongside its significance of supplying most of the early copper to Britain in the Beaker period (Bray 2016). At Ross Island, 10 furnace pits were excavated from phase 2A, all firmly dated to the Beaker period. Furnace pit C.1034 is noteworthy: this had a diameter of 1.07m E–W, 0.70m N–S and a depth of 0.25–0.35 m, with a small furnace structure found at its base. This furnace was made from courses of small stones packed with finer sediments before a final course of three larger stones. The interior measured 0.08–0.11m E–W and 0.17m N–S, with a depth of c.0.12m. The site contained clear evidence of ore processing, crushing and then smelting, although no finished metal artefacts were found during the excavations. No evidence of tuyeres or crucibles was found, and there was no indication of furnace lining in the smelting structures (O'Brien 2004). This evidence suggests that Beaker-period smelting furnaces are liable to be very small scale, and not associated with a furnace lining.

Another possible small-scale copper smelting area was excavated at the Great Orme, at Pentrywn, Wales; this is again located outside the primary area being considered, but it is the only known prehistoric copper-smelting site in Britain. Here, a small conical pit (030), 0.04m wide and 0.12m deep was excavated. It was filled with charcoal-rich silt (029), and also contained fragments of slag, copper prills, and some vitrified material. Charcoal from this feature produced a radiocarbon date of 1755–1415 cal BC (2 sigma) (Hopewell and Jones 1999), although a revised Late Bronze Age date has now been suggested by more recent radiocarbon dating (Williams 2013). Subsequent excavations revealed two further small pits, pit 111 and pit 109, both having fills containing metallurgical debris and charcoal. Both features were sub-circular in plan, with pit 109 0.1m in diameter and pit 111 0.09m in diameter, with pit 111 having a distinctive collar at its top, possibly for insertion of a tuyere blow pipe. The fill of pit 111 was dated to the Late Bronze Age: 968–809 cal BC (2 sigma) (Smith et al. 2011). A replica of the holes was used to smelt a small amount of copper successfully, leaving very little vitrification on the sides of the pits, similar to the excavated examples (Chapman and Chapman 2013). The evidence from Pentrwyn suggests that a Bronze Age furnace might appear on excavation to be a small posthole or stake hole, with some evidence of burning, rather than as a specific feature associated with metalworking. From the evidence so far recovered, it would appear that smelting was undertaken close to the source of the original ore.

The earliest example of a Bronze Age metalworking location in southern England comes from roundhouse 1 at Tremough, Cornwall (Jones et al. 2015) (Figure 4). Excavation of a Middle Bronze Age hollow-set roundhouse led to the recovery of nine bivalve moulds on the house floor, located in the area of a hearth. An assemblage of worked stone also included hammerstones and pestles which could have been used during the later stages of metalworking. Conventional sampling resulted in the recovery of droplets of copper alloy. The hearth was initially identified as being associated with metalworking because of the presence of moulds (Figure 5) (Jones et al. 2015, 180). Had the moulds not been found, it is unlikely that the hearth would have been identified with metalworking. At Trethellen Farm, Cornwall (Nowakowski 1991), the excavation of a Middle Bronze Age roundhouse (142/3022) discovered a 'fire-pit' located on the southern side of the pre-existing house hollow, which probably post-dated the main occupation of the house. The final use of this pit was evidenced by a fill and surrounding spread of burnt material, pottery and some hard-fired clay lumps. A small quantity of copper alloy waste and detritus were found around the pit, although it was not possible to identify this feature definitively as a metalworking/smelting structure.

| Metal-working stage | Types of potential archaeological 'macroscopic' excavation evidence | Observations on current understanding | Archaeological identification issue |

|---|---|---|---|

| Ore preparation/roasting | Crushed ore; fired pits | Only known current excavated examples are associated with mining sites, e.g. Ross Island and Alderley Edge. Crushed cassiterite pebbles are also associated with an Early Bronze Age pit at Truro. | Sites containing hammerspall from mining/processing have been identified during the excavation of the mining sites. Sites of ore preparation likely to be visible during excavation due to macroscopic hammespall, spoil and heated pits containing some ore residue from crushing. |

| Smelting | Hearth/furnace/evidence of heating, prepared ore, slag, tuyeres, crucibles, furnace lining | No definitively identified Beaker/Bronze Age copper or tin smelting sites within Britain, but analogies with Western Europe suggest they are likely to occur close to mining sites (Roberts 2009, 470). Furnaces identified at Ross Island (Ireland) and probably the Great Orme (Pentrywn). Tin slag found at Caerloggas enclosure barrow I (Miles 1975). | Limited visibility – slag deposits could be microscopic and have very low visibility during excavation. The 'furnace' is likely to have an archaeological form similar to a hearth or burnt pit and thus not definable as a metalworking structure per se, during excavation. Evidence from Ross Island suggests Chalcolithic furnaces could be associated with a pit. |

| Casting | Hearth/furnace/evidence of heating, moulds, tuyeres, metal flash from casting | Deposition of moulds has been found on multiple sites throughout Britain. Example of a Middle Bronze Age metalworking roundhouse at Tremough, associated with moulds. | Moulds are liable to be structured deposits and not left lying around the area of casting. Casting likely to use crucibles in a hearth, with the archaeological evidence of a hearth or burnt pit and thus not definable as a metalworking structure per se during excavation. |

| Cold working | Cold working tools, e.g. anvils, cushions tones, hammers, etc. | No definite evidence in the British archaeological record of locations where cold working occurred, but metalworking tools recovered from burials associated with cold working/artefact finishing (e.g. cushion stones in Beaker/Early Bronze Age burials, etc). | Metal filings/residue. Highly unlikely to be visible during excavation. |

| Finished product | Deposits in burials and settlement sites; hoards | Multiple hoards and individual find spots have been found, but none in direct association with metalworking infrastructure such as hearths. Multiple examples of Beaker/Bronze Age burials containing metal artefacts. | Artefacts: thousands known in Britain and Ireland from between c.2500 cal BC and 800 cal BC. |

In contrast to direct in situ evidence of metalworking activity, redeposited materials associated with metalworking are more common during the Bronze Age. Evidence from smelting is still exceedingly rare, with evidence for casting more prevalent from the Middle Bronze Age onwards (Bayley et al. 2008). The description, distribution and analysis of moulds for casting copper alloy artefacts has been well documented (e.g. Britton 1963; Tylecote 1986; Webley and Adams 2016). However, these moulds do not define where metalworking was occurring, indicating rather that items used for metalworking have been incorporated only rarely into hoard deposits or into the structure of some archaeological sites, possibly as foundation deposits (Needham 2007, 285). However, it is possible that such areas where moulds have been found are close to the locations where metals were worked.

Some examples of this 'indirect' evidence include Dainton, Devon, where a small pit close to the southern edge of a cairn was found to contain Late Bronze Age bronze-working debris including mould and crucible fragments with three small fragments of bronze, along with some coarse pot sherds and slabs of local tuff (Needham 1980). Similar material was found around the feature as a possible surface spread. At Norton Fitzwarren, Somerset (Ellis 1989), a large posthole adjacent to an entrance into a Late Bronze Age palisaded enclosure contained 70 mould fragments, probably representing a single mould used to cast a Ewart Park-type sword. Mould debris for casting weapons was also found at the Late Bronze Age enclosure at Springfield Lyons, Essex (Needham and Bridgford 2013, 66), where the debris had been deposited into the northern ditch terminals of the western and eastern entrances. Likewise, at the Mucking South Ring, metalwork and metalworking debris was concentrated around the inner ditch circuit (Evans et al. 2016, 157).

Another interesting, and earlier, example of 'ex situ' evidence are the Caerloggas tin slags, where remnants of tin slag from a smelting process were found in an enclosure barrow constructed around a rocky outcrop, along with other deposits which included a fragment from a Camerton-Snowshill dagger, flints and white quartz pebbles (Miles 1975). This find is interesting for two reasons: firstly, only a very small amount of slag is derived from smelting cassiterite, and secondly, the incorporation of a metal slag into a barrow structure where it appears to have been part of a 'structured deposit' and might have been making a symbolic connection with the transformative process of metalworking. Similarly, newly obtained Early Bronze Age radiocarbon dates from two pits excavated near Truro, each containing both processed and unprocessed cassiterite pebbles, pottery and a stone muller which was laid across the top of one of pits (Taylor forthcoming), points to the 'structured deposition' of a highly valued resource.

Another significant deposit of material associated with metalworking comes from the infilling of Shaft X at Grimes Graves, dating to Phase II (Middle Bronze Age) and Phase I (post Middle Bronze Age). This material is interpreted as midden deposits dumped into the shaft, presumably from the nearby settlement (Longworth et al. 1991). In total 156 fragments of clay refractories were recovered and are interpreted as a limited episode of casting involving only a few moulds, to cast channel-bladed, basal-looped spearheads (Needham 1991a, 154). The assemblage dumped into Shaft X again does not indicate casting was occurring within the shaft, but that casting could have occurred on the nearby Middle Bronze Age settlement. The excavation on this settlement also produced 23 pieces of bronze casting debris, including a miscast spearhead fragment (Needham 1991b, 175). It is therefore probable that this Middle Bronze Age settlement close to Grimes Graves did indeed contain a bronze smith's workplace, the precise location of which has not been identified.

Excavation of a Middle to Late Bronze Age site at Mile Oak, Sussex, recovered copper lead alloy droplets and objects and a fragment of crucible with copper alloy attached. These were found at the soil/chalk interface adjacent to two mounds containing fire-cracked flint, charcoal and baked clay fragments. Within this excavation area (K), 101 cut features were identified (Russell 2002). It is likely that the mounds represent waste from several processes associated with heating, one of which is almost certainly metalworking, although the presence of fire-cracked flints is unlikely to be directly associated with metalworking. The mounds are unlikely to represent in situ furnaces or hearths, but given the number of cut features within the excavation area and the clustering of the copper alloy fragments, it is likely to represent an area where metalworking was occurring in the Late Bronze Age.

The recovery of metal hoards, especially so-called 'founder's hoards', was once interpreted as possible evidence for 'itinerant smiths' (Childe 1930, 45). There has been significant movement away from such functionalist explanations for the presence of such hoards, using the landscape and social context as a key to interpreting these deposits (e.g. Bradley 1991; 2017; Barber 2003, 44–61). These finds do not identify where metalworking has occurred, as clearly defined by Needham (1988, 232), nor that they are necessarily in close proximity to past metalworking. A classic example is the Migdale hoard from Scotland (Needham 2004), which although it demonstrates a distinct metalworking tradition, does not define the location of the metalworking activity.

Further evidence for metalworking has been retrieved from Early Bronze Age burials, one example being the aforementioned metalworking toolkit from the Early Bronze Age Upton Lovell G2a assemblage (Needham 2011, 113–17). Sponge fingers have been suggested to be metalworking tools and have been recovered from a number of Beaker period burials, e.g. the Sarsen burial, Durrington Walls, although their connection to metalworking has been disputed (Woodward and Hunter 2015). A large tin bead from a composite necklace and a tin-studded woven armband, both from an Early Bronze Age cist burial at Whitehorse Hill on Dartmoor, also indicate extraction and smelting of the tin from a source in Devon/Cornwall (Jones 2016), something that has long been postulated (Budd and Gale 1997) but which requires further isotopic work to establish sources.

More circumstantial evidence of metalworking is the arrival of source material into a region of an artefact type not typical for that area, such as the Middle Bronze Age winged median axes which were imported into southern Britain from Northern France/Low Countries (Needham 2007, 282). Found in a shipwreck in Langdon Bay (Needham et al. 2013, 23–50), they are virtually absent from the terrestrial archaeological record. This has been taken to indicate recasting of this artefact type into more socially acceptable forms in southern England, many miles from the continental ore sources. As Needham (2007, 282) highlights, most communities in the Beaker period and Bronze Age would have lived in non-metalliferous areas, so distinct artefact styles localised to a region can be argued to represent evidence of metalworking. This demonstrates a knowledge of metalworking well away from the ultimate source of the metals, and potentially indicates that life histories and the rebirth of artefacts/objects might have important symbolic connotations.

All of this 'indirect' evidence hints that metalworking was a more widespread phenomenon throughout southern England than the current paucity of evidence indicates. However, despite all the indirect evidence indicating access to metalliferous resources, and the casting/recycling of metals, it only demonstrates that metalworking was occurring; it does not identify the locations where metalworking was occurring or who was undertaking these processes. There is still precious little evidence of furnaces, smith working areas or metalworking hearths. This indirect evidence, which is more abundant than the direct in situ evidence, supports the notion that the identification of features associated with metalworking during the excavation of a site is problematic at the macro-level and requires additional information to be retrieved at the micro-level. This indirect evidence also indicates that metals, and their production, were extremely important to Beaker and Bronze Age societies and that metallurgy is also likely to have been a 'magical' process with controls over where, when and who undertook it. This aspect is indicated by the inclusion of the materials used in the production of metal artefacts, such as moulds or casting debris, in 'structured deposits' within sites, such as Dainton, or more exceptionally sealed within a roundhouse as at Tremough and Trethellen. Similarly, materials produced during smelting are incorporated into the Caerloggas I barrow (slag), and the Whitehorse burial (tin bead), showing a connection between tin and ceremonial monuments, the latter perhaps suggesting a direct association between production and use of metals and the transformation (burial) of people.

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.