This appendix presents the attributes and variables that were recorded for each potsherd in the Mahurjhari assemblage during the ceramic recording and analysis process. The reasons for recording these features are outlined above. Here, we present the variables and attributes that were recorded, and details of how they were recorded. This includes the pre-defined qualitative and quantitative values that were assigned to certain variables or attributes, a corresponding account of the scales or visual references used to explain and justify the values that were used, as well as explanations regarding the ways in which certain measurements were taken and to what scale. These details are presented in exactly the same order used during the recording process. All records were entered into a spreadsheet (Microsoft Excel).

Note: the details presented in this appendix (or the text of this article) should by no means be taken as a complete guide to the recording of archaeological ceramics, for which a number of easily accessible resources exist (e.g. Orton et al. 1993; Orton and Hughes 2013).

The unique identifier applied to each potsherd. In our study, we used the following formula: Site code/Trench number/Layer or unit/sherd number. Thus, the first sherd to be recorded from site MHR02, Trench F, Unit 4 would be recorded as: MHR02/F/4/1.

The basic record of the context, locus or unit in which the potsherd was found, using the same nomenclature and numbering system that was used in the excavation.

Trench: The trench in which the sherd was found.

Square: The excavation square within the trench in which the sherd was found.

Context/Layer: The specific context, or layer number the sherd came from. Obviously, the terminology would be adjusted as necessary depending on how the site was excavated.

Feature: The feature the sherd was associated with (e.g. the ditch or pit in which it was found) if any.

This broad category includes details of all visually discernible aspects of the fabric of the potsherd. These were recorded in order to identify and define the initial stages of production used in the formulation of pottery classes. Information recorded in this category also formed the basis for our identification and definition of the Fabric Groups used in the production of ceramics in this assemblage (see Lefrancq and Hawkes 2019a).

All details were recorded from fresh breaks in the potsherd. Breaks were made manually using a pair of pliers on the edge of a sherd, in an area that was deemed to be most representative of that sherd. Where possible, this was on the body portion of a sherd and not the rim or base, as it was recognised that the thickness of the fabric in these parts may present different characteristics than those evident in the profile of the body of a vessel. In order to avoid making multiple breaks, they were made on parts of the sherd deemed to be of average thickness for that sherd.

The first category of fabric information recorded was its colour, and any differences in colour that might be evident in the profile of the sherd (i.e. whether or not there is any variation in colour, whether the internal core differs in colour from its margins, and whether or not the transition between these colours is diffuse or clearly defined). This is an important indicator of the firing environment in which the pot was made. Wherever possible, sherds were examined and these data recorded in natural light to avoid any distortion of colours caused by artificial light. This was the same for all other recorded data.

First, the colour of the core was recorded. We defined the core as the central portion of the profile of a sherd where that portion differed in colour from one or both margins. The colour of the core was recorded using the following variables:

Munsell Colour: The Munsell code of the colour, with reference to the Munsell soil chart.

Colour Description: The Munsell colour (in words), with reference to the Munsell soil chart.

Diffuse?: Whether or not the core exhibits a diffuse transition towards one or both margins or either the external or internal surface. Requires a yes/no answer.

Margins?: Whether or not there are margins to the fabric core (i.e. the fabric differs in colour towards the edges of the profile from the centre). Requires only a yes/no answer. If 'no' then we took the core colour to be the colour of the fabric as visible in the section. If 'yes' then we recorded details of the colours of the margin(s) (see below).

Details of the colour and nature of the change of colour from the margin(s) to either the external or internal surface (if any). These details were recorded for as many margins as were visible in the section. Usually, there were only two margins (one external and one internal). In instances where there was no internal core between the two margins, only details for the margins were recorded. The absence of any details of core colour in the record would then indicate that exactly half of the profile was one colour, and the other half another colour. However, if the majority of the profile was one colour and there was only one margin, then the predominant colour would be recorded as the 'core', and the secondary colour as a 'margin' (either external or internal).

Munsell Colour: The Munsell code of the colour, with reference to the Munsell soil chart.

Colour Description: The Munsell colour (in words), with reference to the Munsell soil chart.

Diffuse?: Whether or not the core exhibits a diffuse transition towards either the external or internal surface of the pot. Requires only a yes/no answer.

Details of the colour of the surface(s) of the sherd where they are visible. In some instances, one or both of the original surfaces were completely obscured by surface treatment (i.e. a slip or slurry), in which case these details were left blank. Details of the surface colour were recorded for both the external and internal surfaces following the same principles as detailed below:

Munsell Colour: The Munsell code of the colour, with reference to the Munsell soil chart. In some instances, it may have been necessary to record more than one colour, for instance if the surface was patchy (see below).

Colour Description: The Munsell colour (in words), with reference to the Munsell soil chart. In some instances, it may have been necessary to record more than one colour, for instance if the surface was patchy (see below).

Patchy?: Whether or not the surface colour is patchy (i.e. not uniform). Requires only a yes/no answer.

Visible in section?: Whether the surface colour was visible in the profile of the sherd (i.e. it is the same colour as the fabric directly beneath the surface — either as part of the margin, or a thin layer that is a different colour from the margin. Requires only a yes/no answer.

The second category of fabric information was details of its texture and feel. This was recorded as an indicator of either the way the vessel was shaped and formed, and/or the conditions under which it was fired.

Hardness: Qualitative classification of the hardness of the fabric, assessed on the basis of how easy it was to make a fresh break of the sherd to reveal the section. This was recorded using pre-defined (subjective) values of 'soft', 'medium' or 'hard', so that the recorded value would be relative between all sherds in the assemblage.

Fracture: The nature of the fracture resulting from a fresh break. This was recorded using the following qualitative values: Conchoidal (where the fracture resembles that of struck flint or glass, with ripples); Smooth (similar to conchoidal but without visible ripples); Regular (where the fracture is neither smooth, nor irregular or hackly); Hackly (where the fracture is highly irregular and appears 'spikey'); Laminated (where the sherd fractures in layers).

Feel: How the natural surface of the sherd feels to the touch. In other words, its relative smoothness. Obviously, this can only be recorded if the natural (i.e. untreated) surface is visible. The same information is recorded (where possible) for both the exterior and interior surfaces, with reference to a pre-defined scale of relative values (with values for individual sherds defined in relation to each other): Very fine/Fine/Medium/Coarse/Very coarse.

Firing: An assessment (based on the hardness, fracture, colour, overall nature of the inclusions, and feel of the surface) as to how well the pot was fired. Recorded with reference to a pre-defined scale of values: Well fired/Under fired/Over fired.

The third category of fabric information relates to details of the inclusions visible in the section of the sherd. This was identified as diagnostic of how the paste was constituted and prepared in order to make the fabric of the pot, as well as indicating certain conditions relating to how the finished vessel was fired. Here, a number of variables and attributes pertaining to each identifiable inclusion visible in the profile of the sherd were recorded.

Inclusion type: The type of inclusion (i.e. its material). Note: a void or pocket where something used to be prior to firing was still counted as an inclusion. Values were entered according to pre-defined list of values: Organic/Sand/Grit/Mica/Grog/Shell/Calcite/Voids/None Visible. It was recognised that this list does not encompass every type of inclusion that could exist. However, it was formed through our experience of examining a range of ceramics from various South Asian contexts, and includes all recurring types that we encountered and that are identifiable through visual inspection. Further types found during examination could be added to this list.

Inclusion colour: The colour of this inclusion, using a pre-defined set list of values: White/Red/Brown /Black/Grey/Silver/Gold/Mixed/No colour. A pre-defined list of values was preferred over a Munsell colour chart owing to the impracticalities of easily and accurately establishing the Munsell colour of small particles. The same set of values was recorded for every inclusion.

Inclusion size: Assessment of the approximate size of these inclusions, with reference to pre-defined values: Very fine (<0.1mm)/Very fine (<0.1mm) to fine (0.1-0.25mm)/Fine (0.1-0.25mm)/Fine (0.1-0.25mm) to medium (0.25-0.5mm)/Medium (0.25-0.5mm)/Medium (0.25-0.5mm) to Coarse (0.5-1mm)/Coarse (0.5-1mm)/Coarse (0.5mm-1mm) to very coarse (>1mm)/Very coarse (>1mm).

Inclusion shape: Identification of shape of inclusion, with reference to Powers' scale of roundness (see Barraclough 1992): Angular/Sub angular/Rounded/Well rounded/Irregular/Elongated/Flat.

Inclusion sorting: Identification of how the inclusions been sorted, as they appear distributed throughout the fabric (as visible in the profile). In other words, whether they all cluster together in one very localised area (very poorly sorted), or are very evenly spread throughout the fabric (very well sorted). Values recorded with reference to existing scales of pebble sorting (see Barraclough 1992): Very poor/Poor/Fair/Well/Very well.

Inclusion frequency: How frequent is the occurrence of this inclusion in the fabric (as a proportion of the fabric). With reference to the percentage inclusion estimation chart (after Mathew et al. 1991): Very sparse (<5%)/Sparse (5-10%)/Moderate (10-20%)/Frequent (>20%).

Following details of the fabric of a sherd, the second broad category of information that was recorded was the way in which its surface(s) had been finished. This encompassed both: (1) the surface finish, i.e. any additional coating that may have been applied to the vessel and how either that (or the uncoated surface of the pot) was treated; as well as (2) the decoration, being any decoration that might have been applied to this coating (or bare surface). The same details were recorded for both the external and internal surfaces of a potsherd.

Details of the following variables were recorded in order to record the surface finish of a sherd.

Coating: Whether the surface of the sherd has been treated with any type of coating. Requires only a yes/no answer.

Coating type: If there are traces of a coating, then an assessment of the type of coating that has been applied to the surface. This was recorded with reference to a pre-defined list of values, based on treatments most commonly found in South Asian record: Wash/Slip/Self-slip/Slurry/Glaze/Bitumen.

Colour: The colour of the surface treatment, with reference to Munsell chart if possible. We recognised that the standard soil chart does not always represent the entire range of colours applied to the surfaces of pots.

Treatment?: Whether the surface of the sherd (either the natural surface of the fabric or the coating that has been applied to it) has been treated using a secondary process in any way. Requires only a yes/no answer.

Treatment type: A record of the type of treatment that has been used, with reference to a pre-defined list of values: Burnishing (horizontal)/Burnishing (vertical)/Burnishing (varied)/Smoothed/Wet smoothed/Shaved/Unidentified (abraded). Where two or more types of treatment are evident, this can be recorded in the 'Treatment description' field (below).

Treatment description: An extra field for any additional notes if required.

Details of the following variables were recorded in order to record any decoration (defined as an additional process differing from a finish or treatment, such as a painted design, incision, or applique) that had been applied to the vessel and visible on the sherd.

Decoration?: Whether or not the exterior surface been decorated in any way. Requires only a yes/no answer.

Decoration type: If yes, a record of how it has been decorated? For more than one type of decoration, additional columns can be added as necessary.

Decoration description: A description of that type of decoration.

The third broad category of information that was recorded related to the form of the vessel, the way it was shaped, and the various dimensions of its (identifiable) elements.

First, we recorded information relating to the type of vessel indicated by the sherd and how it appeared to have been formed.

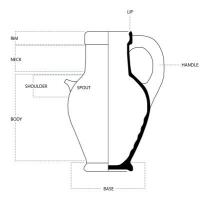

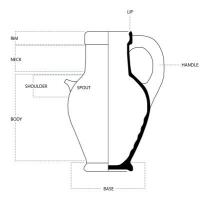

Sherd type: The type of sherd as defined by the part of the vessel it was from (see Figure 41). Recorded with reference to a pre-defined list: Rim/Base/Body/Neck/Shoulder/Spout/Handle/Complete profile/Complete vessel. Where more than one element of the profile could be identified (e.g. rim and neck), the most diagnostic feature takes precedence.

Vessel form: Vessel form as an indicator of the vessel's primary function (assumed on the basis of its shape), with reference to a pre-defined list of vessel 'types' familiar to those working in the South Asian context: Amphora/Bowl/Dish/Globular Pot/Jar/Lid/Miniature vessel/Necked vessel/Spouted vessel/Storage Jar/Unidentified.

Manufacturing technique: What type of technique(s) was used to make this vessel? Wheel/Slow wheel Hand/Hand-formed and wheel finished/Moulded/Unidentified.

The shape and size of a sherd, with all measurements taken using digital callipers, accurate to one millimetre.

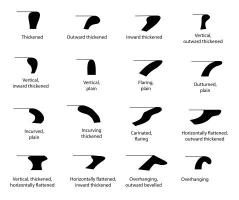

Rim type: The type of rim profile defined and recorded with reference to a pre-defined (but by no means exhaustive) descriptive list of rim types (see Figure 42): Vertical/Flaring/Horizontally flaring/Out-turned/Incurved/Overhanging/Carinated flaring/Carinated out-turned/Carinated incurved.

Rim shape: The precise shape of the rim lip, recorded with reference to a pre-defined list of terms: Plain/Thickened/Inward thickened/Outward thickened/Horizontally flattened/Horizontally flattened and thickened/Horizontally flattened and outwardly thickened/Horizontally flattened and inwardly thickened/Outward bevelled/Inward bevelled.

Rim diameter: In centimetres, using a rim chart.

% Surviving: The percentage of the original diameter of the rim that survives, rounded to the nearest 5%, using a rim chart.

Base type: The type of base that is evident, with reference to a pre-defined list of criteria: Round/Flat/Disc/Ring/Footed/String cut.

Base diameter: In centimetres, using a rim chart.

% Surviving: The percentage of the original diameter of the base that survives, rounded to nearest 5%, using a rim chart.

A record of the thickness of each constituent part of the vessel (where more than one element of the profile is present). If only an unidentifiable bodysherd has survived, then only the body thickness need be recorded.

Body thickness: The thickness of the body of the vessel, taken from the widest point visible in section.

Rim thickness: The thickness of the widest part of the rim (perpendicular to the angle of curve).

Neck thickness: Thickness of neck of vessel (if visible and identifiable in profile), taken from the widest point visible in section.

Shoulder thickness: Thickness of shoulder of vessel (if visible and identifiable in profile), taken from the widest point visible in section.

Base thickness: Thickness of base of vessel (if visible in profile). Measurement taken from as close to the centre of the base as possible.

Sherd height: Height of sherd (where it is possible to ascertain original orientation). If original orientation is not possible, the greatest length.

Sherd width: Width of sherd (perpendicular to height).

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.